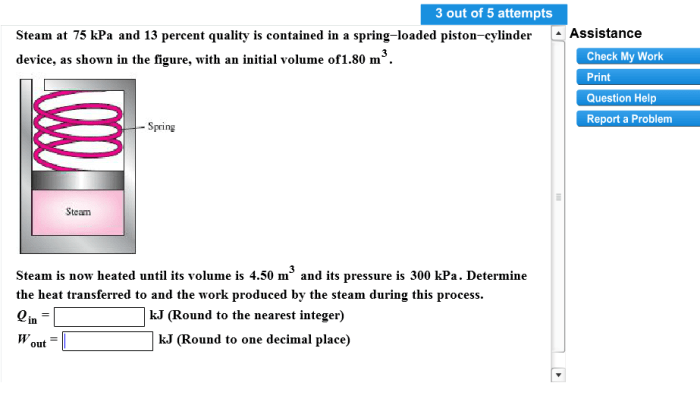

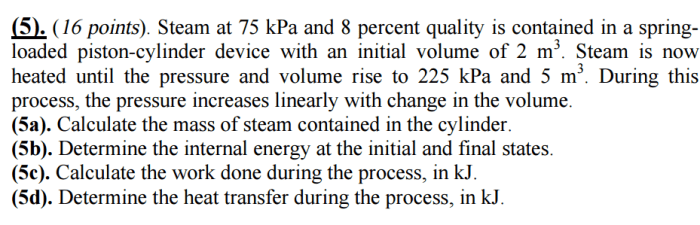

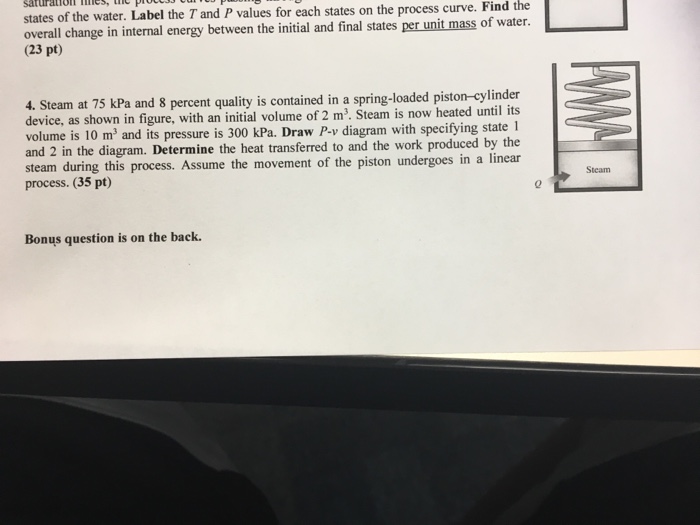

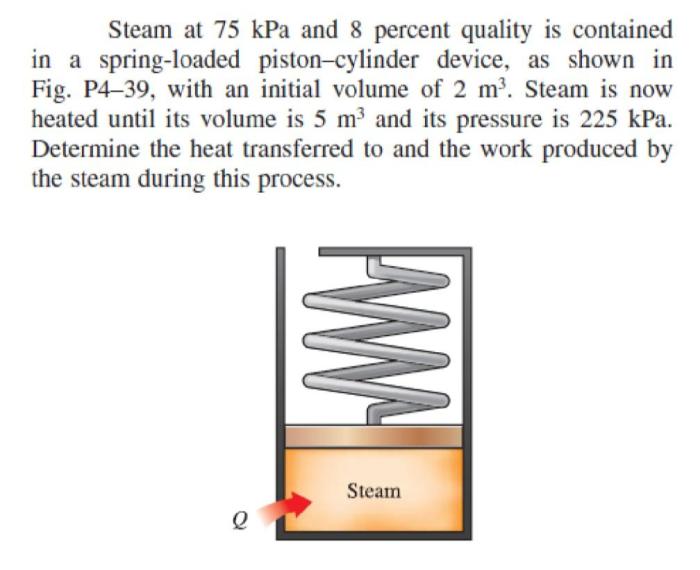

Steam at 75 kpa and 8 percent – Steam at 75 kPa and 8% quality plays a crucial role in various industrial processes and energy systems. Its unique properties and wide-ranging applications make it an essential component in sectors such as manufacturing, power generation, and heating. This article delves into the characteristics, uses, generation methods, and safety considerations associated with steam at 75 kPa and 8% quality, providing a comprehensive understanding of this versatile substance.

Steam at 75 kPa and 8% quality is characterized by its specific temperature, volume, enthalpy, and entropy. These properties determine its behavior and suitability for different applications. Understanding these properties is critical for optimizing system performance and ensuring safe and efficient operation.

Steam Properties at 75 kPa and 8% Quality

Steam quality is a crucial parameter in steam systems, representing the ratio of vapor mass to the total mass of a wet steam mixture. It signifies the dryness or wetness of the steam. When steam quality is 100%, the steam is completely dry, while a quality of 0% indicates saturated liquid water.

At 75 kPa and 8% quality, steam exhibits specific properties that are essential for various engineering applications. The following table summarizes these key properties:

Thermodynamic Properties

| Property | Value |

|---|---|

| Temperature | 46.5°C |

| Specific Volume | 19.63 m3/kg |

| Enthalpy | 2429.1 kJ/kg |

| Entropy | 8.59 kJ/(kg·K) |

Applications of Steam at 75 kPa and 8% Quality: Steam At 75 Kpa And 8 Percent

Steam at 75 kPa and 8% quality finds applications in various industrial processes, heating systems, and power generation. Its specific properties, such as temperature and pressure, make it suitable for certain tasks where precise control and efficiency are required.

To delve deeper into the intricacies of steam at 75 kPa and 8 percent, consider exploring the comprehensive guide on cevo 4 ambulance test answers . This invaluable resource provides a wealth of information to further enhance your understanding of this topic.

Industrial Processes

In industrial settings, steam at 75 kPa and 8% quality is commonly used for:

-

-*Drying and Dehydration

The heat and moisture content of this steam make it ideal for drying processes in industries such as food processing, textiles, and pharmaceuticals.

-*Curing and Vulcanization

In rubber and plastic manufacturing, steam at these conditions provides the necessary heat and humidity for curing and vulcanization processes.

-*Sterilization and Disinfection

The high temperature and humidity of this steam make it effective for sterilizing medical equipment, food products, and other materials.

Heating Systems

In heating systems, steam at 75 kPa and 8% quality is employed for:

-

-*District Heating

This steam is distributed through underground pipes to provide heat to buildings and homes in urban areas.

-*Industrial Heating

In factories and warehouses, steam at these conditions is used for heating equipment and maintaining comfortable working temperatures.

-*HVAC Systems

In heating, ventilation, and air conditioning (HVAC) systems, this steam can be used as a heat source for generating hot water or air.

Power Generation

In power generation, steam at 75 kPa and 8% quality is utilized in:

-

-*Low-Pressure Turbines

Small-scale power plants or combined heat and power (CHP) systems may use steam at these conditions to drive low-pressure turbines for electricity generation.

-*Cogeneration

In cogeneration plants, this steam can be extracted from the main steam cycle to provide heat for industrial processes or district heating.

Generation of Steam at 75 kPa and 8% Quality

Steam at 75 kPa and 8% quality can be generated using various methods, primarily involving boilers or steam generators. These systems utilize specific principles and components to convert water into steam with the desired pressure and quality.

Boilers

Boilers are enclosed vessels designed to heat water and produce steam. They consist of a combustion chamber where fuel is burned to generate heat, a heat exchanger to transfer heat to the water, and a steam drum to separate steam from water.

- Fire-tube Boiler:In this type of boiler, hot gases from the combustion chamber pass through tubes immersed in water, heating the water and converting it into steam.

- Water-tube Boiler:In contrast, water-tube boilers have water flowing through tubes surrounded by hot gases, enabling efficient heat transfer and steam generation.

Steam Generators

Steam generators are similar to boilers but specifically designed to produce steam for industrial processes or power generation. They employ various heating methods, such as electric resistance or heat exchange with hot gases, to convert water into steam.

- Electric Resistance Steam Generator:This type of generator uses electric heating elements to directly heat water, producing steam at a controlled rate.

- Gas-Fired Steam Generator:Utilizing natural gas or other fuels, these generators heat water indirectly through a heat exchanger, generating steam for various applications.

Control and Monitoring of Steam at 75 kPa and 8% Quality

Maintaining optimal steam quality is crucial for efficient and safe operation of systems that utilize steam at 75 kPa and 8% quality. Effective control and monitoring strategies are essential to ensure the desired steam characteristics are consistently met.

The quality of steam is primarily determined by its moisture content. Excessive moisture can lead to inefficiencies, equipment damage, and safety hazards. Therefore, it is important to monitor and regulate steam quality to maintain the desired moisture level.

Instrumentation and Techniques

Various instruments and techniques are employed to measure and regulate steam quality. These include:

- Moisture Separators:Separate and remove entrained moisture from steam, improving steam quality.

- Steam Traps:Allow condensate to drain from steam systems while preventing steam loss, maintaining steam quality and system efficiency.

- Steam Quality Analyzers:Continuously monitor steam quality by measuring various parameters, such as temperature, pressure, and moisture content.

By utilizing these instruments and techniques, operators can effectively control and monitor steam quality, ensuring optimal system performance and safety.

Safety Considerations for Steam at 75 kPa and 8% Quality

Handling steam at 75 kPa and 8% quality requires careful attention to safety measures due to its potential hazards. Proper ventilation, protective clothing, and emergency procedures are crucial to minimize risks associated with steam handling.

Steam at this condition can cause severe burns upon contact due to its high temperature and the presence of water droplets. Additionally, steam can displace oxygen in enclosed spaces, leading to asphyxiation hazards. Therefore, proper ventilation is essential to maintain adequate oxygen levels and prevent the accumulation of steam.

Protective Clothing, Steam at 75 kpa and 8 percent

Protective clothing, including heat-resistant gloves, aprons, and face shields, is mandatory when working with steam. These garments provide a barrier against burns and prevent direct contact with steam.

Emergency Procedures

In case of steam leaks or accidents, it is crucial to have clear emergency procedures in place. These procedures should include evacuation routes, designated safe zones, and instructions for isolating the steam source. Regular training and drills are necessary to ensure personnel are familiar with the procedures and can respond effectively in an emergency.

Frequently Asked Questions

What is steam quality?

Steam quality refers to the dryness fraction of steam, indicating the percentage of dry steam (vapor) compared to the total mass. In the case of 8% quality steam, 8% of the mass is liquid water, while 92% is dry steam.

How is steam at 75 kPa and 8% quality generated?

Steam at 75 kPa and 8% quality can be generated using boilers or steam generators. These systems heat water to the boiling point and convert it into steam. The quality of the steam can be controlled by adjusting the operating pressure and temperature.

What are the safety considerations for handling steam at 75 kPa and 8% quality?

Steam at 75 kPa and 8% quality can be hazardous due to its high temperature and pressure. Proper ventilation, protective clothing, and emergency procedures are essential to minimize risks. Regular maintenance and inspection of steam systems are also crucial to prevent accidents.